LSK-Wintrich

Main menu:

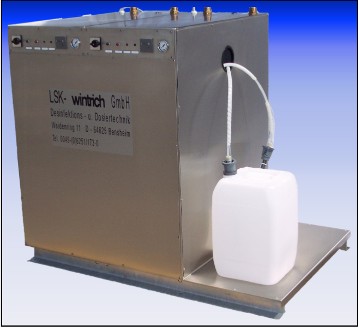

Winco System 3022 / 4022 / 5022 / 6022

products > electronically-controled dispensing centres

3000 / 4000 / 5000 / 6000 l/h pipe isolated

Accordant to DIN 1988 and the worksheet W 503 from the DVGW (German Association of Water and Gas) compact model.

The adjustment charge between 0.25% and 3.0% for continuous and constant adding of disinfectant solution concentrate to the tap water. As a central supply station it affords an economic supplement from the disinfectant solution tapping.

Application areas:

Hospitals, industry, swimming-pools, laundries, animal and food areas, test animal culture institutes, laboratories, sewage works, and waste discharge units.

BAM DDE 18

| Concentration: Adjustable for the most common, water soluble disinfectant solutions and cleaning concentrates. Adding: Adjustable from 0.25% to 3.0%. Construction: Robust, easy to maintain and to operate, long-living. Shut-off: Automatically shut-off when disinfection solution concentration shortage. |

|

D010352 D010360 D010365 D010370 |

Disinfectant solution dosing unit at a system construction as: Fabrikat LSK-Wintrich 3022 - 3000 l/h, 6,0 bar Fabrikat LSK-Wintrich 4022 - 4000 l/h, 6,0 bar Fabrikat LSK-Wintrich 5022 - 5000 l/h, 6,0 bar Fabrikat LSK-Wintrich 6022 - 6000 l/h, 6,0 bar In general consisting of: 2 pipe isolators as DIN 1988 and worksheet W 503 from the DVGW as a plastic seal housing, free water inlet per magnetic valve above level-controlled, safety overflow and dry run safety for booster pumps. 4 rotary pumps for pressure increase until 6.0 bar shut-off pressure 400 V, 50 Hz, rating 1.1 kW, 3.2 A, 2,900/minute, type of protection IP 44 2 contactors for quantity based tap to control the metering pump 4 metering units as reciprocating plunger type pumps with disinfectant solution resistant parts, 230 V, 50 Hz 2 TÜV certificated diaphragms pressure box with prestressed butyl diaphragm, total capacity 2 x 8 litres 2 VDE proofed plastic control boxes with control electronic for level controlling and supplement dosing of the disinfectant solution 2 plastic suction tubes with seal cone foot valve to tap disinfectant solution from the barrel 1 complete piping of the equipment made of none corroding material 1 double stainless-steel box, material 1.4301, grounded with a collateral parking space for supply concentration Instrument panel: Control switch: off - on Manometer: 0 - 10 bar Hour counter: four-digit Signal lights: Ready to use: green Concentrate (reserve): yellow Concentrate (empty): red Motor fault: red Housing dimensions: L x W x H = 1000 x 800 x 1180 mm dimension sheet M 172 Connections Disinfectant solution tapping: 2 x R ¾" Water inlet: 2 x R 1" Safety overflow: 2 x R 1 ¼" Electric: 5 x R 1,5 " Weight: 180 kg approx. |

| 1 set operation and service manual Accessories if requested (not included in our delivery) 1 first filling: 25 l barrel capacity (not part of our delivery) 1 second filling: 25 l barrel capacity (not part of our delivery) |

|

| D010395 | 1 remote signaling to ZLT (special equipment on request) Delivery terms: ex work, excl. packing Delivery period: 2 - 3 weeks approx. Payment: 14 days 2% discount, 30 days net |

| D900010 | Installation and operator training is carried out by LSK-Wintrich staff. The guarantee period is controlled by legal regulations. Equipment is supplied in accordance with the general terms and conditions of LSK-Wintrich. Assembly, connection and filling are not included in our contract of sale. Maintenance contract as per BAM guideline from 1978; price per maintenance on request. Note: Please install into the extraction line a sample outlet valve! |